For example, in the case of clothing, a thinner material can be used to create a shirt or jacket without sacrificing quality. However, if you want to increase the thickness of your materials, you will need to use more material and pay more for it. Also, technological advancements have led to the manufacturing sector becoming increasingly automated, which has increased the production of goods. As a result, there is now a greater demand for human capital that can operate machines and oversee their operation. This has increased the demand for skilled workers, which has led to higher wages and labor costs.

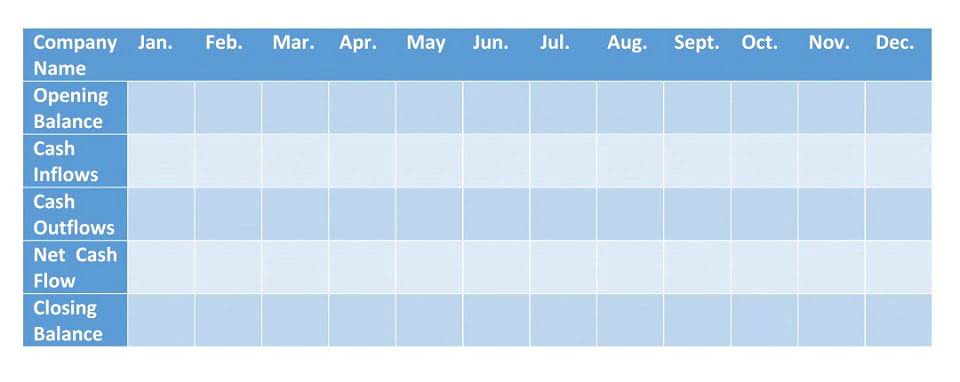

Benefit #5: Guides investment decisions

A word used by accountants to communicate that an expense has occurred and needs to be recognized on the income statement even though no payment was made. The second part of the necessary entry will be a credit to a liability account. We recommend taking our Practice nonmanufacturing costs include Quiz next, and then continuing with the rest of our Nonmanufacturing Overhead materials (see the full outline below).

Example #4: Indirect manufacturing costs (factory overheads)

- This article looks at meaning of and differences between two main cost categories for a manufacturing entity – manufacturing cost and non-manufacturing cost.

- Next, calculate the value of the existing inventory if the manufacturing company already has a stock of materials from a previous period.

- The total direct manufacturing costs are usually expressed as a percentage of the sales price for each product.

- If you’re hiring workers to work on your manufacturing line, you can reduce your costs by hiring people who are more efficient at their jobs.

- Examples include advertising costs, salaries and commission of sales personnel, storage costs, shipping and delivery, and customer service.

Under the accrual basis of accounting, the matching is NOT based on the date that the expenses are paid. Direct materials – cost of items that form an integral part of the finished product. Examples include wood in furniture, steel in automobile, water in bottled drink, fabric in shirt, etc. Gain insights to optimize your manufacturing expenses and boost profitability. With all this valuable information under your belt, you can better track manufacturing costs as they pertain to your workforce.

Applying Non-Manufacturing Costing Methods

Another example is if you were making a t-shirt, the cotton and thread would be considered direct materials. While depreciation on manufacturing equipment is considered a manufacturing cost, depreciation on the warehouse in which products are held after they are made is considered a period cost. While carrying raw materials and partially completed products is a manufacturing cost, delivering finished products from the warehouse to clients is a period expense. For accounting purposes, nonmanufacturing costs are expensed periodically (typically in the period they are incurred). However, for management objectives, managers frequently require the assignment of nonmanufacturing costs to goods. This is especially true for specific product-related commissions and promotions.

The cost of inventory should include all costs necessary to acquire the items and to get them ready for sale. It is important to distinguish manufacturing costs from non-manufacturing costs, as these categories affect how expenses are reported and managed. Non-manufacturing costs are essential for a business’s overall operation but are not directly tied to the production process Mental Health Billing itself. Total manufacturing cost represents the aggregate financial outlay a company incurs to produce its goods.

Practical Applications in Managerial Accounting

Fluctuation of costs is yet another challenge that makes it harder to calculate manufacturing costs accurately, according to Fabrizi. The petty cash next step is to calculate the costs of utilities (electricity, water, or gas) that are directly used in the manufacturing process (for example, fuel used to operate the production equipment). Then, add up the cost of new inventory — this is the cost of raw materials you purchase to manufacture the product. Let’s go through all the steps for calculating total manufacturing costs.

- Therefore, you should always consult with accounting and tax professionals for assistance with your specific circumstances.

- Examples of marketing and selling costs include advertising costs, order taking costs and salaries of sales persons etc.

- As a result, many companies have had trouble hiring qualified candidates and remain understaffed even after offering higher wages than competitors in their industry.

- Non-manufacturing costs include those costs that are not incurred in the production process but are incurred for other business activities of the entity.

Non-manufacturing costs include sales commissions, advertising, office supplies, rent/mortgage payments for company offices, and legal fees. Anything that isn’t directly tied to manufacturing or transporting your products. In the end, management should know whether each product’s selling price is adequate to cover the product’s manufacturing costs, nonmanufacturing costs, and required profit. Fixed manufacturing costs are those expenses that do not change in total, regardless of the volume of goods produced within a relevant range and time period.